Here's the build saga:

Project started as the classic $500 Jeep I towed home in December 1996:

I scrapped the body, and picked up a 'new' OEM steel tub from Willys-Overland in Toledo. This was welded up from NOS stampings. The fenders, dash, and windshield frame are all aftermarket (Taiwan) stampings. The grill is a genuine Jeep (Chrysler) item. Hood is the only remaining body part from the original Jeep. The corners and rockers are from 'off your rocker'.

I've also recently added highback seats and a tilt column (no pics of that yet):

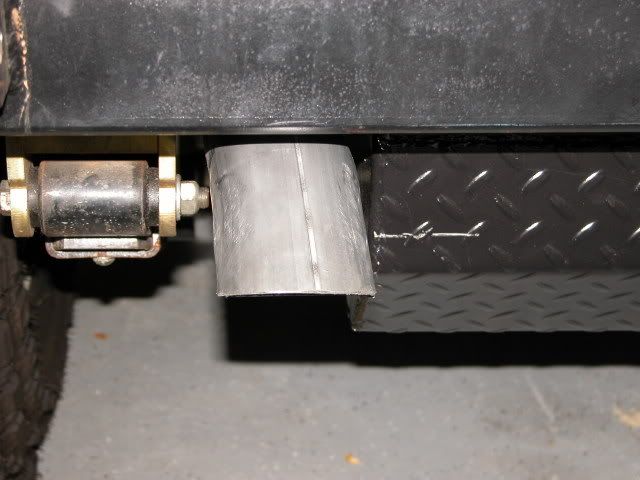

I had the stock frame boxed and a six-point roll cage built (Performance Off-Road in Alexandria, KY) along with rock sliders, although I don't have a pic of the tub with the cage installed.

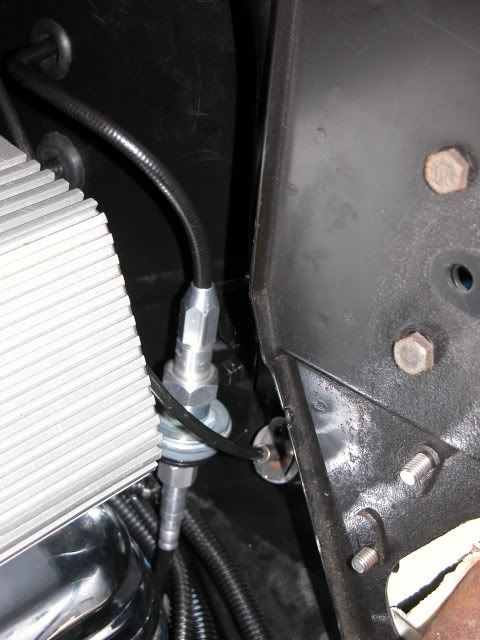

The axles are stock narrow track Dana 30 / AMC 20. I converted the front to disc brakes using parts off an 84 CJ. The rear has Moser 1pc axles and 11" drums. Both have been regeared to 4.56 and have ARB lockers with stainless steel lines. They're hung on a BDS 2.5" SUA lift with ConFer 3/4" shackles. It's riding on a set of 32x11.50x15 TSL/SX tires, which are a disappointing 30.5" tall. Gonna go to a 34x9.50x15 TSL for replacements. Or go metric with 16" wheels.

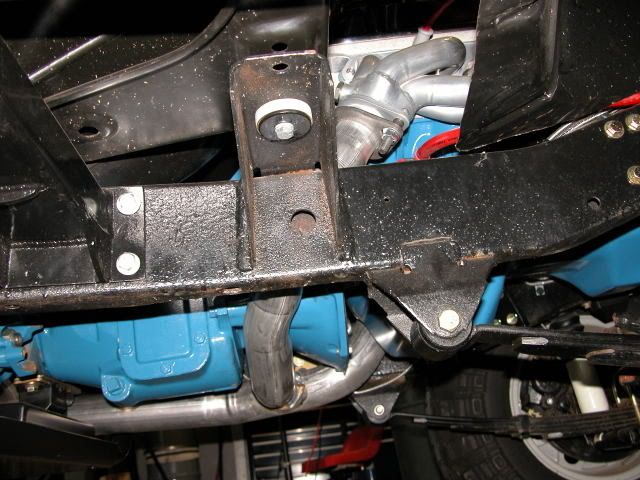

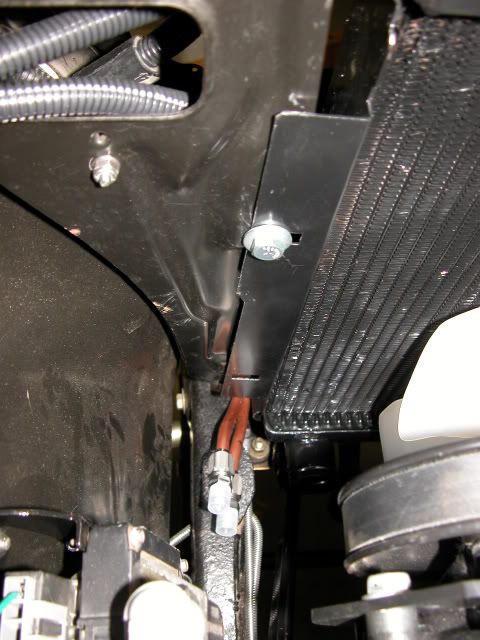

Using the M.O.R.E. mounts caused some 'issues' with the stock skidplate/crossmember. I ended up ordering one from Throttle Down Kustoms and having to custom machine a new stabilzer stud because the Energy Suspension trans mount is 'taller' than a stock mount:

It also placed the clutch fork arm real close to where the combination valve was supposed to mount:

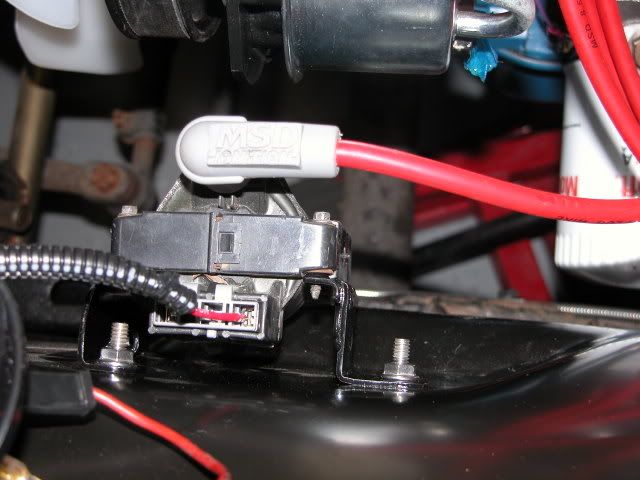

I ended up relocating it to get better clearance:

Also had to 'cut the trans opening a bit':

All the brake lines are stainless steel that I purchased from Inline Tube (along with the combo valve). I'm debating whether to go vacuum or hydoboost. Money is naturally a factor.

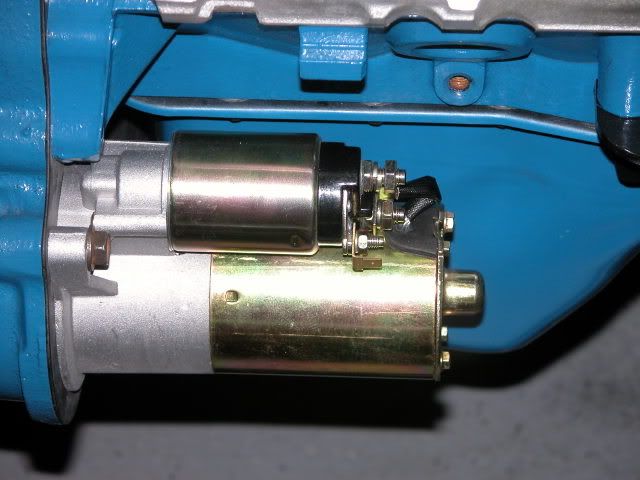

The motor is a Ford Racing GT40 5.0L Crate Engine. One of my 'better' purchases off eBay. It came with the GT40 tubular manifold, B cam, 65mm TB, 24# injectors (and a whole lot of other Mustang stuff that got sold). I added the Ford Racing F-150 headers (had them Jet-Hot coated), and the Saginaw PS pump conversion was done with a bracket from Wild Horses and a Ford Racing AC eliminator kit. I removed the smog pump and smoothed off the bracket. The alternator is a 160amp unit from RJM Injection Technology as is the computer harness. I'm running a Goodyear 74.75" serp belt. The starter is a mini PMGR I picked up locally:

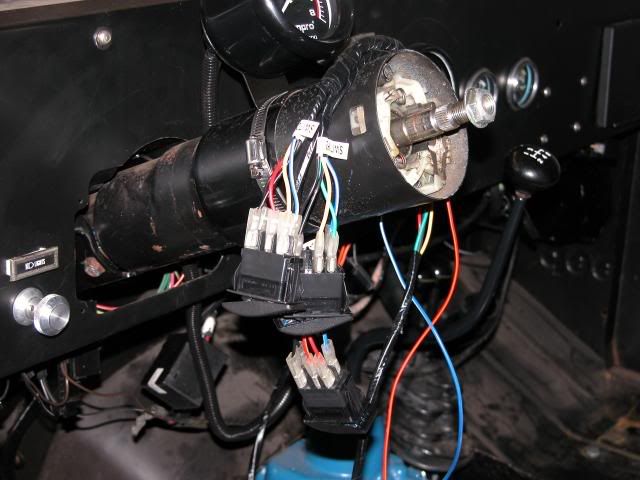

I'm hiding the ECM (A9L) behind the dash above the heater box (which was totally rebuilt and upgraded to a 3spd fan):

The VSS is mounted on the firewall and connected with two cables from Lokar. You can also see how I Hack Fab'd the stock Mustang throttle cable:

I hid the Inertia Switch inside the Tuffy Glovebox:

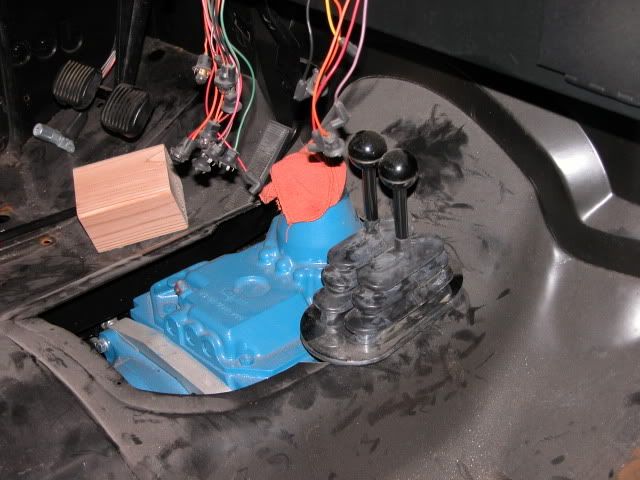

The transmission is a Ford T18 that I picked up (literally off the ground at Stevenson's in Highland-Damn I miss that place!) for $35. It was rebuilt, the stock CJ T18 shifter adapted to it, and I used the Jeep T18b mainshaft along with an adapter from Advance to mate it to the rebuilt, TeraLow'd, and twinstik'd Dana 20:

The clutch is a LuK 11" pro gold. I Hack Fab'd up a clutch linkage bracket for the z-bar which allows me to use the stock Jeep CJ mechanical clutch:

Here's how I worked the return spring issue:

The custom intank fuel pump for my TrailQuest 23gal tank (not a 'bolt on' by any means) was Hack Fab'd from a stock Jeep CJ pickup/sender and a stock Mustang unit (another eBay item with a 255lph pump):

I was going to use stainless hard lines along the frame, but they proved too difficult to bend. So I went with stainless braided line from Russell and an Aeromotive inline filter:

Dealing with the mess:

I purchased the aftermarket replacement speedometer. What a pos. Sent it right back. Ended up finding a used OEM and taking the guts out of my 76's and putting them in the used case. My original was rusted through in one spot, and the fuel/temp gauges were shot. This worked out much better. Still looking for 'the right' oil pressure and voltmeter. The aftermarket ones are also crap...Sent those back too. Will probably use either Autometer or SW. Leaning toward SW as they were who Jeep used as a supplier. Had I to do this again...I would have went total custom dash. I just don't want to change directions now.

Finally, Finally got the intermittent wiper conversion to work. Turned out it was a bad (brand new, aftermarket, OMIX) 4 wire motor. I sent that back and although I've got a real nice used original....

Reply With Quote

Reply With Quote